JAPSPEED & DIEMAX ENGINEERING

With teams and drivers in the drifting world constantly striving for the best engineering to allow them to push harder and get ever closer to those all-important clipping points it is no wonder that sooner or later there will be some teething pains. This is almost certainly going to be the case when you push those boundaries so far as Japspeed have done with the new supercharged V8 370z piloted by Shane Lynch!

In the case of this particular build the team found that the standard 370z steering pump simply couldn’t keep up with the demand in terms of output pressure from the VH45 powerhouse that has squeezed into the bay from Shane’s S15 of previous years. Added to this the power steering has been known to be a little dubious as standard on the very early 370z models. Of course Nissan were quick to rectify this and have since greatly increased the pressure put through the rack on newer models to make it easier to use.

In the sport of drifting it is extremely important to save time in the pits as much as possible so we decided to retro fit an older steering rack from a 350z into the car. This would mean that our steering pumps would work better but it also meant that if we needed to replace the rack at any point it should be simpler to source a 350z rack rather than a 370z rack due to the age of the car.

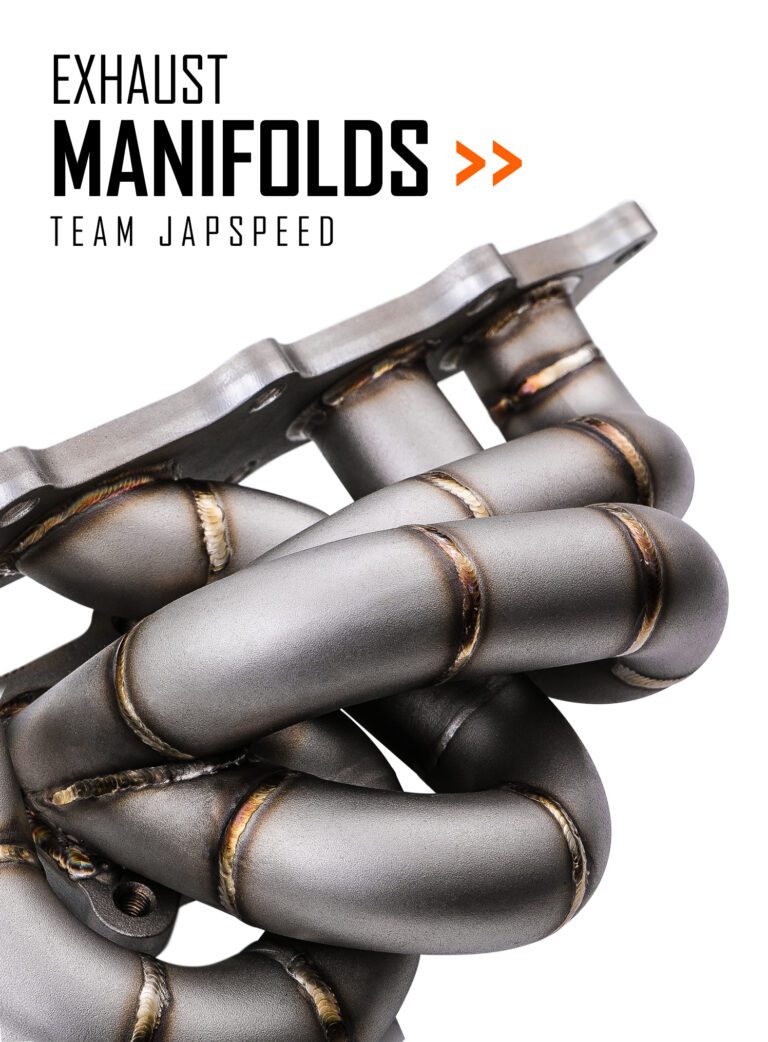

It all sounded great in principal but as with any custom build it would turn out to be easier said than done. The issue we faced was that the 350z rack mounted at 90° to the 370z and with space already limited in the 370z subframe thanks to the V8 engine alongside custom manifolds and sump; fitting the rack may not be so straightforward.

To combat the problem our engineers worked alongside the team at Diemax Engineering to create a custom adapter plate which would bolt the full rack assembly from underneath the car with 6 bolts into the subframe. Not only did it resolve the issue but should we ever need to remove the rack we can now quickly as easily remove the complete assembly via only 6 bolts to provide full clear access.

We’d like to take this opportunity to send a HUGE THANKS to the team at Diemax Precision Engineering Ltd for their part in bringing this to reality.